Our Product Development Process

Innovating for the field

From concept to completion, our product development process ensures rugged, reliable, and ready-for-action solutions. Whether it’s a new control system, a custom-built enclosure, or a full-scale prototype — we engineer for real-world results.

This approach combines cutting-edge CAD design, mechanical insight, and rapid prototyping to get your solution from sketch to shop floor—fast.

Concept Design

We collaborate with your team to define ideas and set design goals.

3D CAD Modelling

Precision 3D modeling for detailed visualization and engineering.

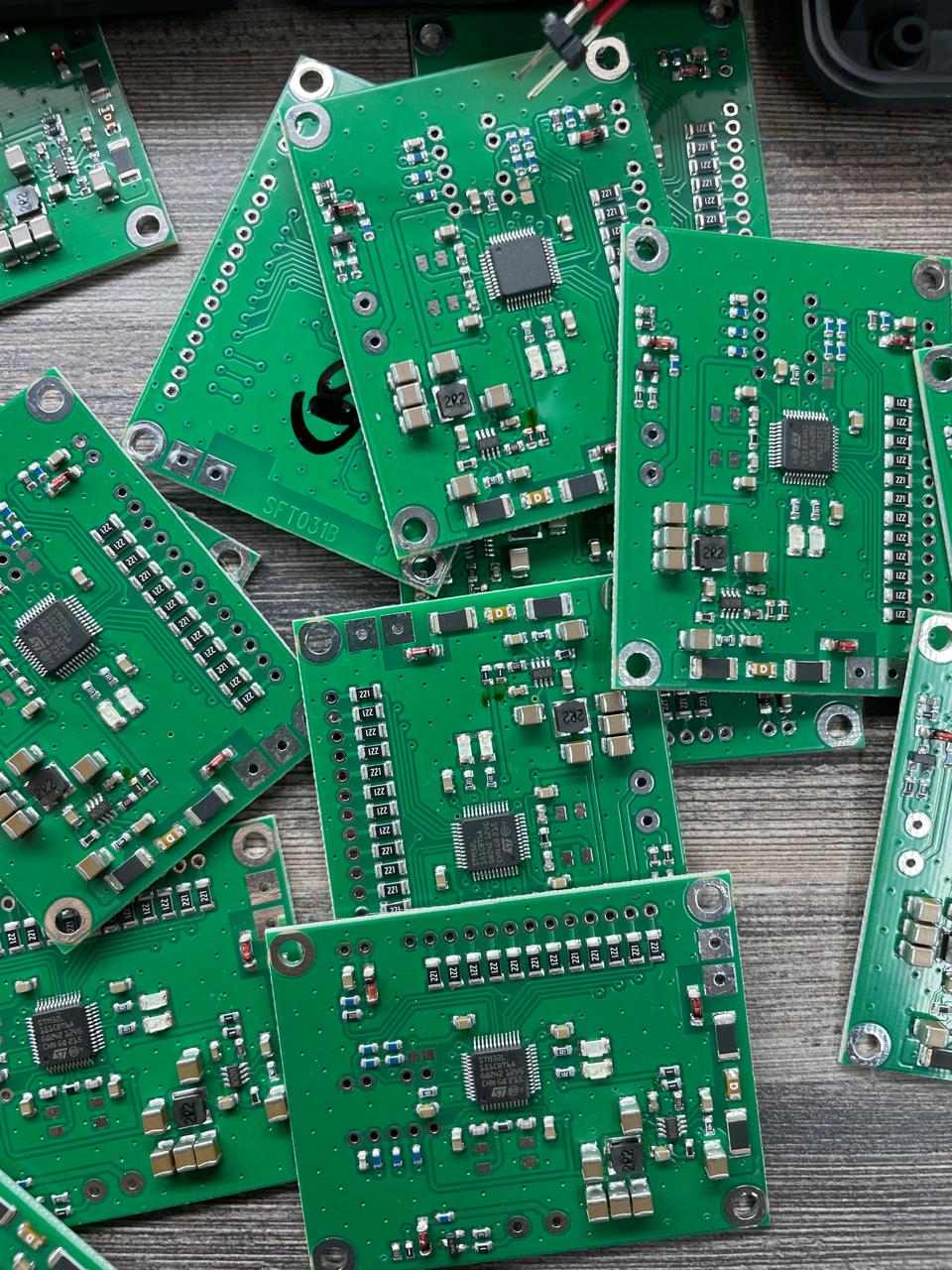

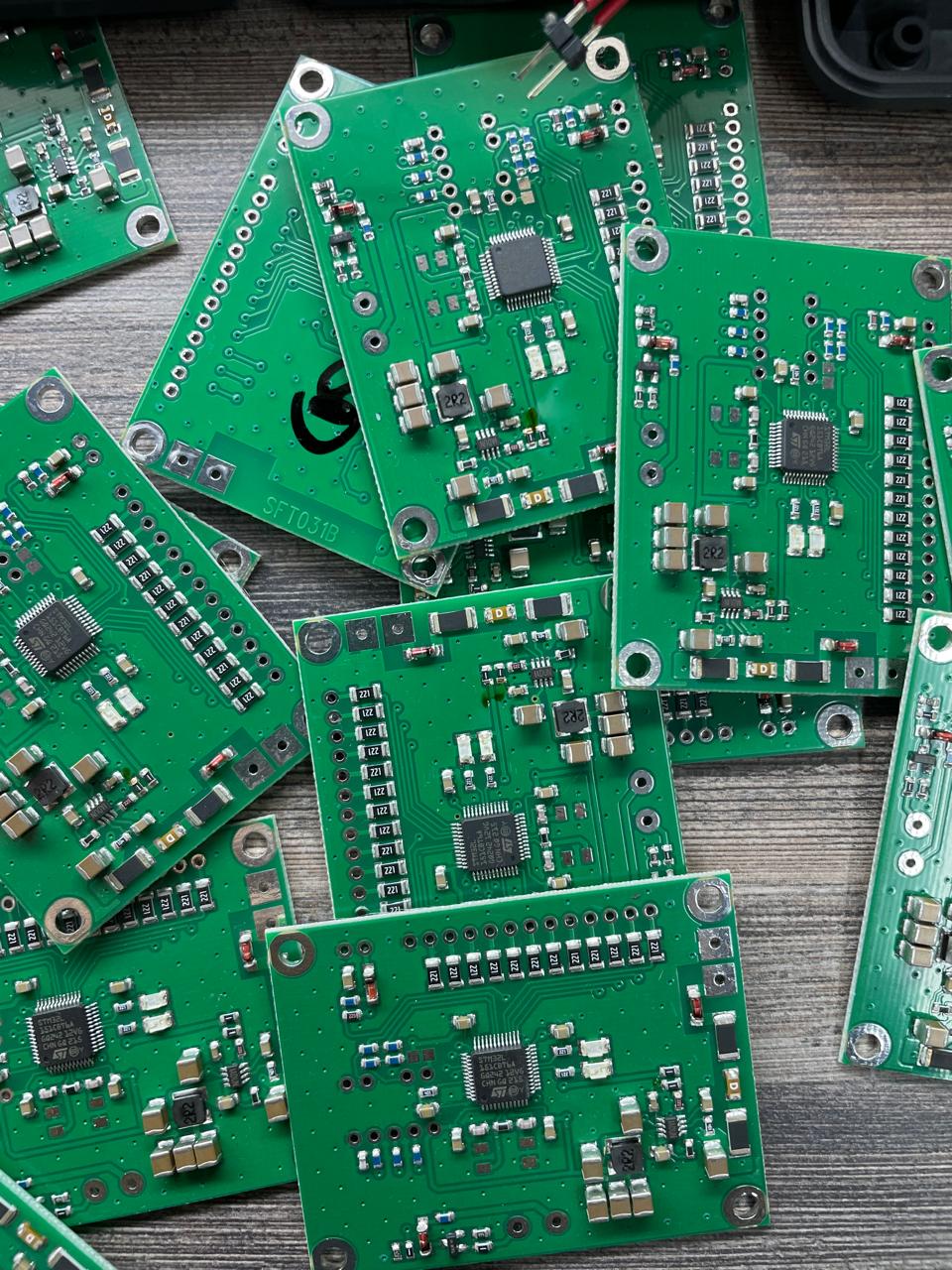

Prototyping

Functional models that bring your concept to life.

Mechanical Engineering

Field-ready, rugged engineering to withstand harsh environments

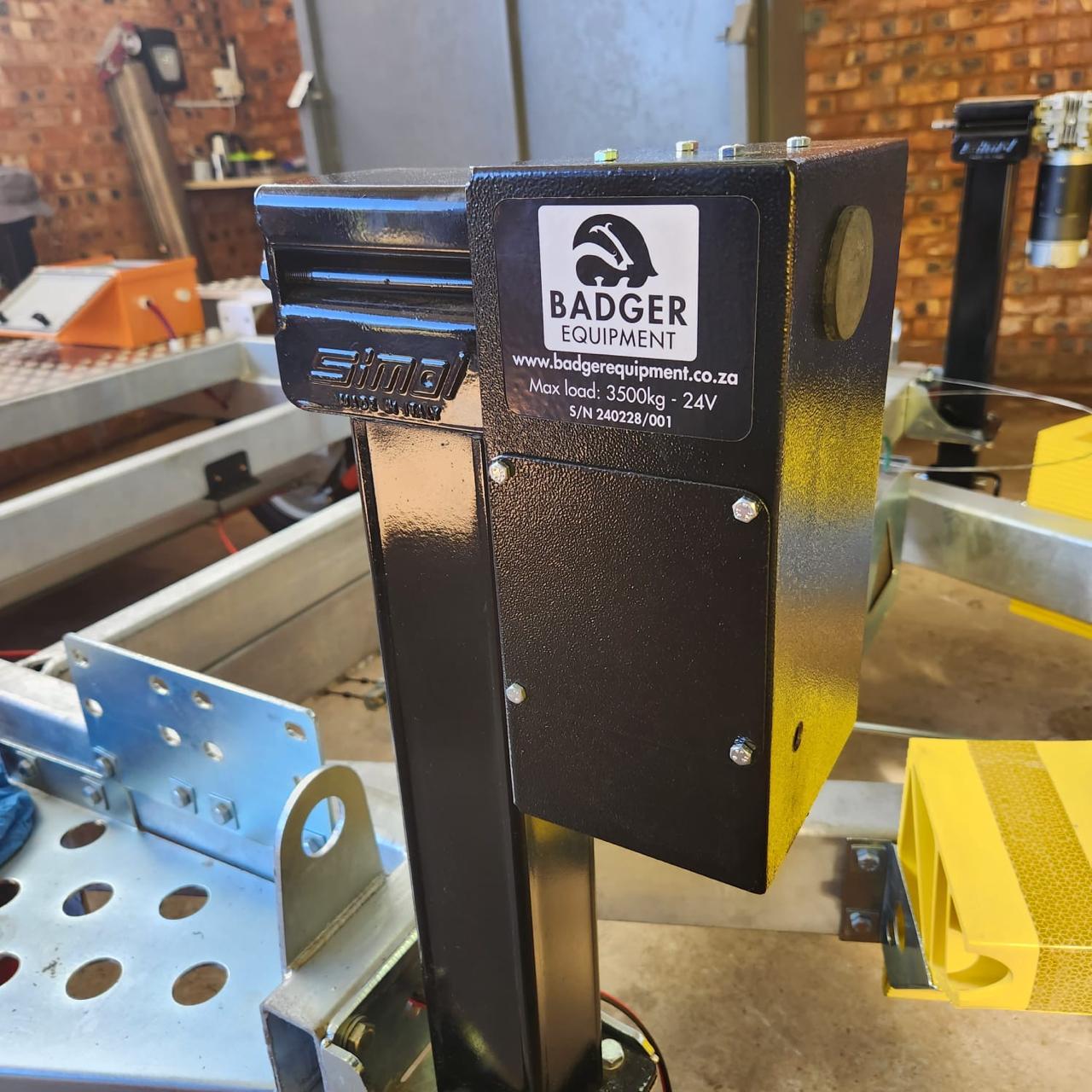

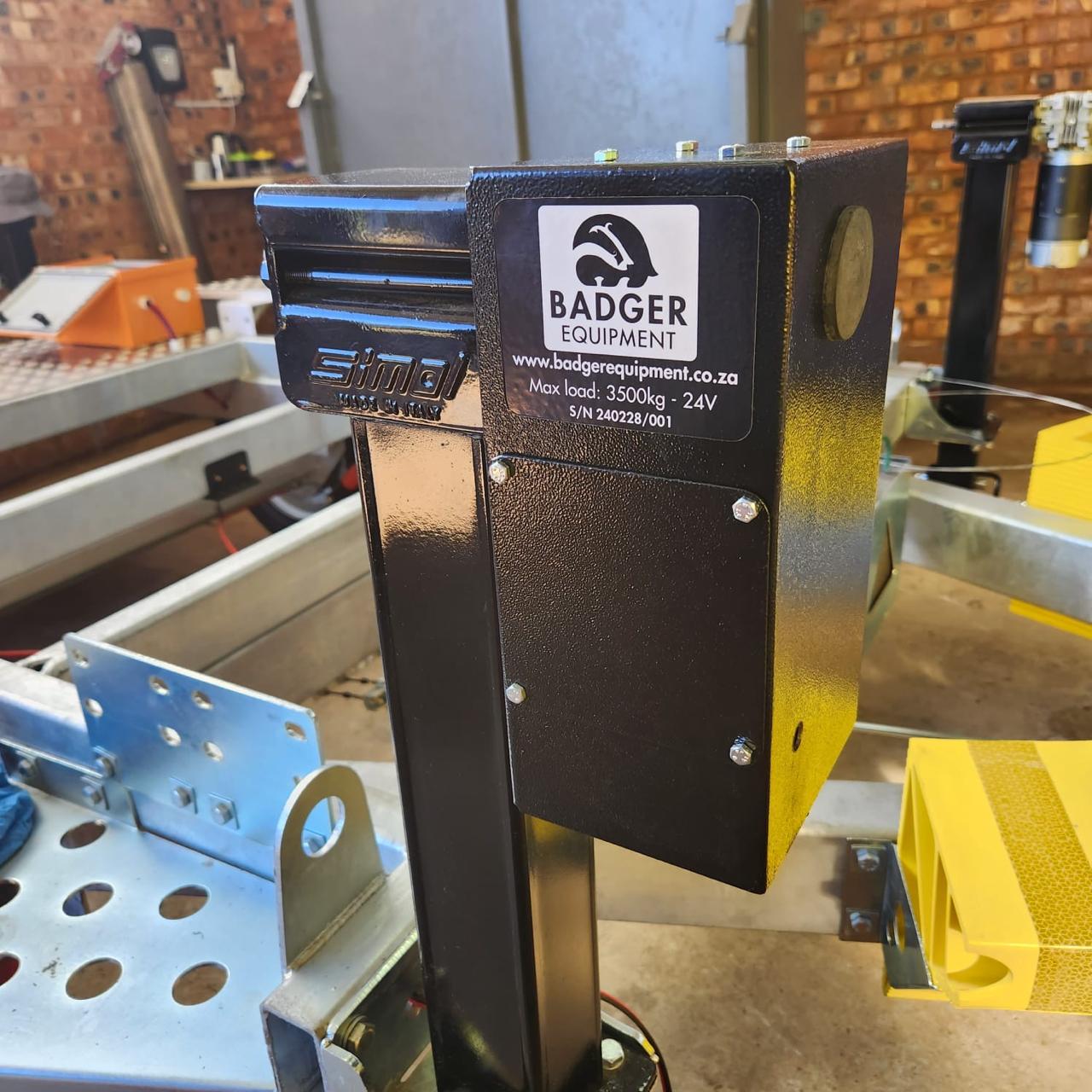

Panel Building

Custom control panels, fully integrated and ready for deployment.

Field Testing

We validate every component in real-world conditions before final delivery.

Engineered for Performance

Every component. Every detail. From concept to completion, we streamline the process to bring your vision to life — fast, reliable, and built to last.

Our Product Development Process

STEP ONE

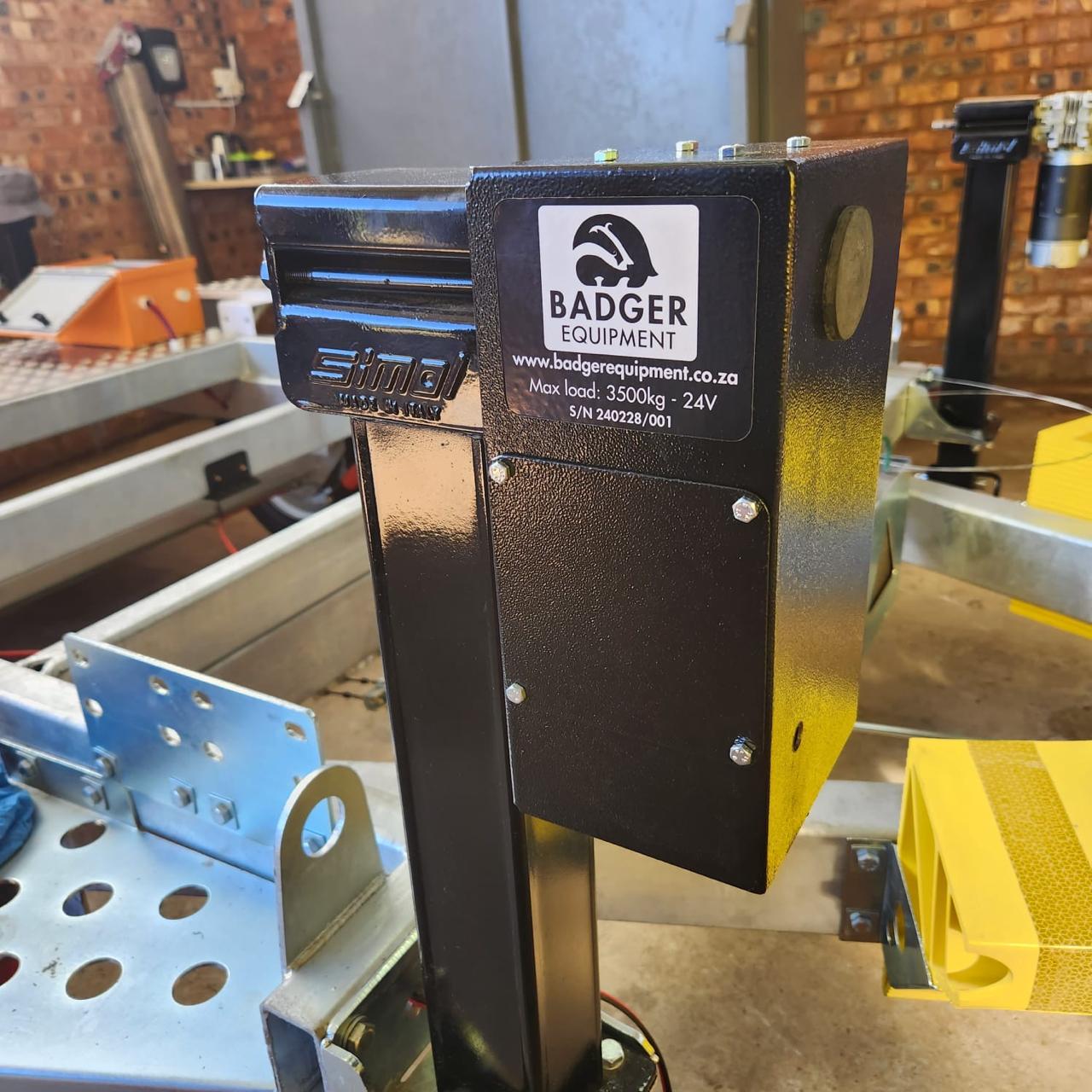

On-Site Assessment

We begin by meeting with the client on-site to evaluate problems and develop a real-world understanding of the challenges at hand.

Issues Tackled

- Trailer too low for radar visibility

- Frame lacks necessary robustness

- No solar panel protection box

- Side steps needed for comfortable access

- Wheels too small for terrain

- Hydraulic leveling unreliable for operator use

STEP TWO

3D Design & Drafting

We take the information gathered from on-site assessments and start building a precise, visual model of your solution. Our engineering team creates full CAD assemblies and workshop-ready blueprints to ensure accuracy and performance.

What You'll Get

- Detailed assembly drawings

- Bending & boiler making diagrams

- Exploded views for clarity

- Blueprints for each part/component

STEP THREE

Engineering & Assembly

Our hands-on production process takes your design into the physical world. From CNC cutting to expert welding and powder coating, we bring precision, strength, and reliability to life — all in-house, all controlled for quality.

Processes & Capabilities

- CNC plasma cutting

- Sheet metal bending & fabrication

- MIG & TIG welding

- Galvanising and rust-proofing

- Powder coating in your color of choice

STEP FOUR

Finishing & Reveal

After all components are cut, bent, welded, and coated, the assembly process brings everything together. This phase is where we see the product come to life — powder-coated, galvanized, and ready for reveal. Built tough. Built to last.

Final Assembly & Reveal

- All components combined into final assembly

- Powder coating in chosen color

- Galvanised parts prepped for longevity

- Final product cleaned and quality checked

- Prepared for deployment to client site

STEP FIVE

Quality Assurance

Our team runs the product through a meticulous in-house quality check process, verifying that every component meets our engineering standards. This guarantees that what leaves our workshop will perform reliably in the field, no exceptions.

What We Check

- Structural integrity of all welds

- Fitment of all moving parts

- Electronics, hydraulic & solar system testing

- Powder coating and galvanising inspection

- Operational stress testing under load

STEP SIX

Field-Tested. Client-Approved.

This is where every hour of design, cutting, and engineering is validated. We deliver the final product to the client’s site and ensure that it performs as expected — in the real world. Whether it’s off-road deployment or industrial site integration, our equipment is built for it.

Deployment Highlights

- Delivered fully assembled to client site

- Tested under real-world conditions

- On-site calibration and fine-tuning

- Training and walk-through with client team

- Live data testing (radar, hydraulics, electronics)

Auto-Level in Action

Watch our tech do the heavy lifting — fully automated, zero compromise.

our Work / Prototypes

Built tough. Prototypes forged from precision and tested for performance.